- Product Configuration

- Technical Parameter

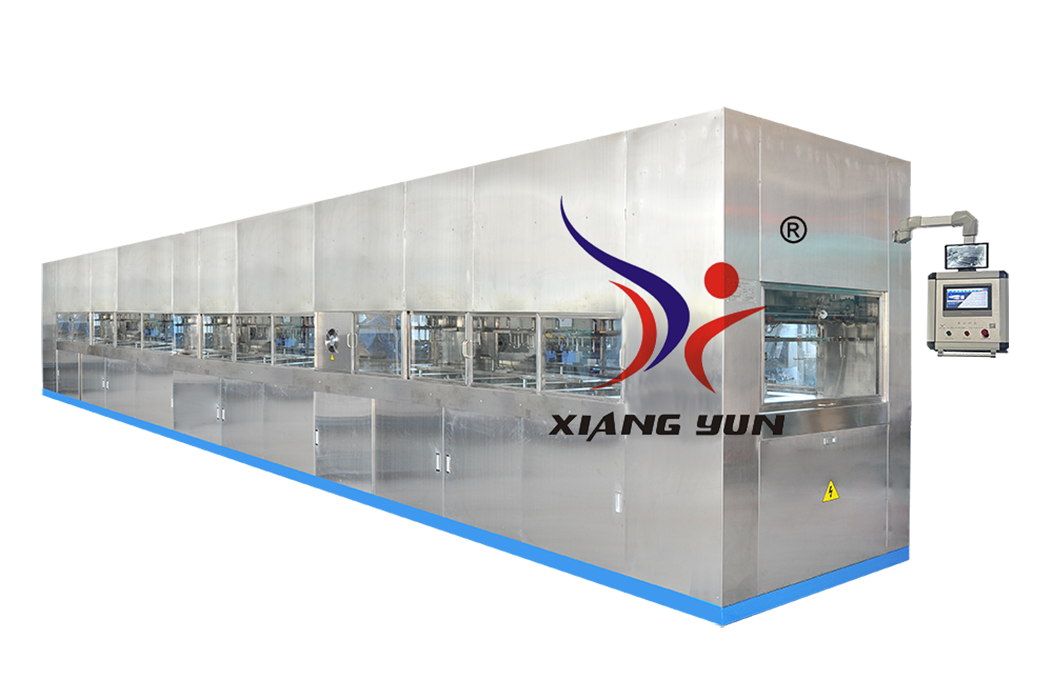

Equipment Profile:

XY-NC6/SK6024H automatic strengthening production line is the sixth generation of automatic intelligent lens strengthening production line improved on XY-NC5 model. Mainly for some non-flat or semi-spherical products surface coating and hardening treatment. This production line should be improved and optimized for many times according to customer demand, so that the equipment performance is more stable and reliable. Because the system adopts intelligent Chinese operation interface and fault warning function, you can easily operate and maintain the machine in a short time.

1. the system by Japan Panasonic servo drive, Taiwan Delta programmable controller (PLC), Shanghai Fanyi 12.1 Internet of Things touch screen composed of intelligent control system. With fault inquiry, sound and light alarm display, data encryption independent adjustable and other functions. Temperature control with PID intelligent die block temperature control, high performance long life stainless steel electric heat pipe hot air circulation heating, safe to rely on. Main interface dynamic display, current power display, fault display, alarm query function, fully digital setting, temperature sub-partition control, equipped with a number of observation Windows, can check the quality of products in the strengthening process at any time.

2. the conveying part adopts bidirectional planar chain conveying, servo motor drive; The lifting part uses a servo motor to control the mechanical arm to remove the product, and after multi-groove ultrasonic cleaning, it is automatically hung on the conveyor chain. Two independent strengthening slots can be strengthened after IPA, or two different kinds of products can be strengthened (one slot puts PC strengthening liquid and the other slot puts PMMA strengthening liquid). The system is free to switch parameters, the cleaning adopts a circulating filter heating device, an independent circulating filter tank, no need to frequently replace the water source and filter system, energy saving and environmental protection.

3. the strengthening line includes drying and curing oven, the whole machine only needs one operator, one time to complete the product cleaning, strengthening, drying process, very convenient to use.

Using Range :

PMMA, PC, PA, TAC, ABS, PET and other plastic products surface coating and hard treatment. Such as: optical lenses, magnifying glasses, vehicle optical products, aviation products, craft accessories, buttons, lighting, camera ball cover, rearview mirror, helmet protective mask, mobile phone Windows, car logo, lights, instrument panels, etc.

Technological Process:

Material loading → Ultrasonic cleaning agent rough washing → Ultrasonic fine washing → Rinsing → Ultrasonic rinsing → Ultrasonic fine washing → ID water cutting → Drying → Cooling → IPA (ethanol soaking cleaning) → Strengthening → Pre drying → Drying and solidification → Natural cooling → Material unloading

Dimension | L20000×W2080×H2780mm (the height does not include the positions of the bower and transmission machinery could be customized) | |

Production Capacity | 240 pieces/hour (8640 for wafer) with total 159 rods ×4 hangs | |

Max. Processing Size of Work Piece | 100×150mm(product dimension) | |

Production Equipment | Strengthening cleaning devices | 5 sets of independent ultrasonic cleanings: 2 set of strengthening ultrasonic, all having filter device |

Ultrasonic parameter | Frequency: 28KHz 220v; power: 2880w×7 sets | |

Filter system | 0.37kw 380v magnetic pump. Stainless steel filter. 4 sets of cleaning, 2 set of strengthening(magnetic pump) | |

Cleaning strengthening lifting system | Mechanical arm lifting structure of synchronous belt module, servo drive motor, power 220v 0.4KW ×5 sets; linear speed: 0-1000mm/min(adjustable) | |

Transmission system | 1.5KW Servo motor drive , 12A two-way precise roller chain synchronous transmission; Linear speed: 0-2000mm/min (adjustable) with 32000mm×2=64000mm as the length of chain. | |

Cooling system | Equip Strengthening Room with 3 air cooling devices, 1 Gree card air conditioning ; cooling system of strengthening liquid: 1.5 sets (1.102KW 220V); one industrial chiller(with a circulating pump whose power is 0.37KW 220V)×2 sets | |

Parameter in Cleaning & drying area | Cleaning and heating (5 slots in total):30KW 380V; cleaning and drying: 13.5KW 380V(4.5KW×3 sets) strengthening & pre-baking, solidification area: 78KW 380V | |

Power | 148.0KW 380V ( actual power consumption:55.0KW/h) | |

Controlling System | Using centralized control system with servo motor, programmable controller (PLC), high-resolution color LCD touch screen (HMI), temperature control section and video monitoring system. It has those protective functions of default checking, sound & light alarm, cleaning, strengthening lifting and transmission chain speed in a way that the time is adjustable and any overheating, losing, over loading, anti-drop protection of strengthening products will be detected by infrared ray. Besides, cumulative counting, current display, line speed display, and other various kinds of protective functions will also be used so that the machine could automatically solve any defaults occurring by showing the reasons and eliminating methods in time. | |