- Product Configuration

- Technical Parameter

Feature :

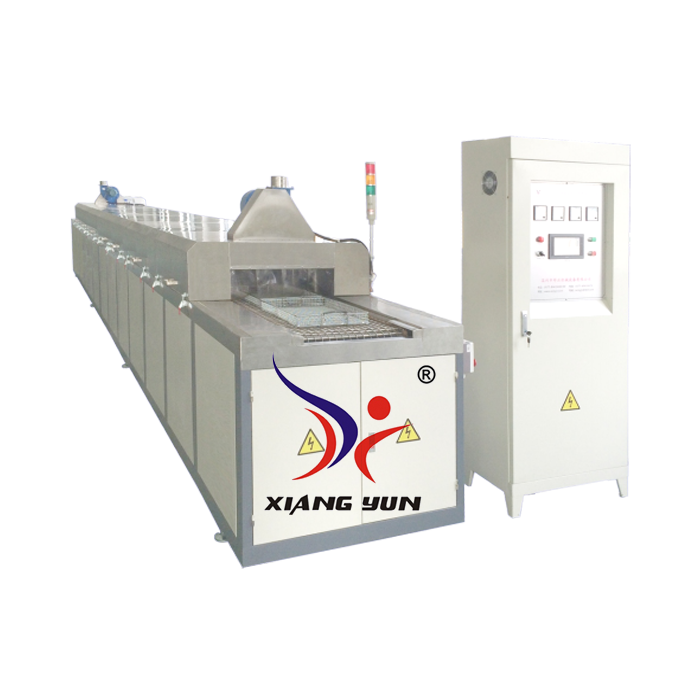

This machine is our company specially designed for batch continuous cleaning operation and high efficiency through the ultrasonic cleaning line! This machine is equipped with high pressure three times spray device (with heating), independent four times filtration system, two times ultrasonic fine washing, three times hot air drying, smoke discharge device, stainless steel conveyor belt, with leakage liquid automatic recovery filter device, easy to use, environmental protection.

The machine has compact structure, novel design, easy to use, can effectively save space and manpower, because of the use of continuous transmission cleaning function, thus greatly improving the production efficiency, is currently a representative of the industry cleaning equipment!

Using Range :

Used for metal and electrical, tableware, auto parts, AC contactor iron core, reducer, door close, ground spring die casting shell and other surface dust and oil for quick automatic water cleaning.

Cleaning Procedure :

Feeding →1 spray →2 spray → Ultrasonic fine washing →3 spray → water rinsing (rust prevention)→1 blow drying →2 blow drying →3 high pressure air drying → cutting

Model | XY-L0508 track type automatic ultrasonic cleaning line | |

Production Equipment | Overall dimension | L10000×W1000×H1250mm (width does not include water tank position) |

Ultrasonic configuration | Three sets (1.8kw×2 +2.4kw×1) 28kw,28KH, digital generator, power adjustable | |

Filter unit | Five sets (2.2kw 380V stainless steel pump centrifugal pump, 10 inch three-core stainless steel filter) | |

Heating system | A: Hot air circulation heating: not equipped B: Heat 5 groups ×6Kw in the sink | |

Other configuration | A: Water vapor exhaust, 2 sets of 3kw blow-drying devices B: Anti-leakage treatment of the whole machine, water leakage recovery device, incoming and outgoing material detection device | |

Transmission system | Japan Nikki 0.75Kw GTR gear reduction motor, stainless steel mesh chain, immersion continuous automatic cleaning | |

Control system | Touch screen, PLC control, temperature module, control integration | |

Overall power | 380V 45KW 380V (Actual power consumption: 18KW/h) | |