- Product Configuration

- Technical Parameter

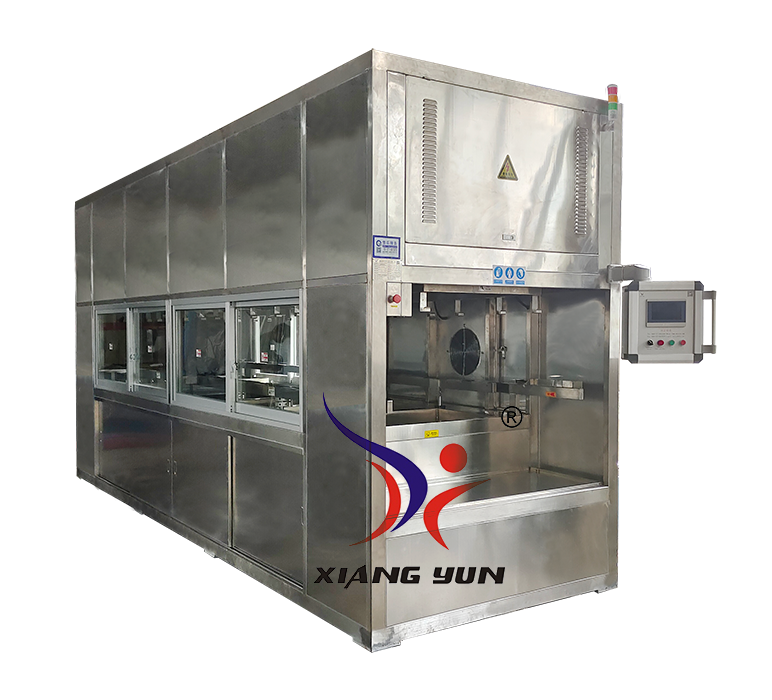

Specification : Six-tank single hanging board (could be customized)

Feature :

The overall structure of the machine is fully integrated with today's international popular design concepts. The appearance is simple and perfect, and the color is soft. Due to the use of PLC(programmable logic controller) and touch screen operation control, the process has reached a fully digital mode, and the production efficiency and product quality have reached the first-class level. It is the current hardware and auto parts industry dedicated high-efficiency ultrasonic cleaning equipment! Ultrasonic 3 sets, each set 2400W, digital control electric heating 5 sets, hot air drying 1 set, stainless steel circulating pump and filter 4 sets. Stainless steel frame tempered glass viewing door, hot air drying device, up and down motion Washing, cleaning basket return transport, independent adjustable footing, centralized into the drainage system to ensure comfortable and fast production.

Using Range :

For door closers, ground springs; Auto ball head, swing arm, direction machine, ball cage, engine housing, hardware plumbing, auto parts and other products cleaning. Set cleaning, drying as one.

Cleaning Procedure :

Feeding → Ultrasonic rough washing of cleaning agent → ultrasonic rinsing → ultrasonic fine washing → water air cutting → water drying → cleaning basket return → cutting

Model | XY-SKCA6002PY automatic ultrasonic cleaning machine | |

L5200×W1650×H2950mm | ||

Ultrasound configuration | 3 groups×2.4kw,28KHZ,power adjustable | |

filtrating equipment | Four sets of 550W 380W stainless steel pump circulatio,10 inch three- core stainless steel filter | |

heating system | A: Hot air circulation heating 1 group ×2.25kw B: Heat 4 groups ×8Kw in the sink C: Two sets of water air cutting fans ×3Kw D: Moisture drying fan 1 set ×1.5Kw | |

Production Equipment | Other configuration | A: 1 set of washing basket return conveyor B: Slow drawing water, circulating heating tank 1 set C: Two water exhaust fans |

drive system | A: 1.5Kw servo motor drives product lift B: 0.75Kw servo motor drives product translation C: 1.5Kw servo motor drive product throwing cleaning | |

Control system | Touch screen, PLC control, temperature module, servo motor, lifting module and other integrated contro | |

The power of the machine | 55KW 380V (Actual power consumption: 20KW/h) | |